Invent HYPERCLASSIC® Mixing and Aeration System

Aeration is the process of adding air or oxygen to the air by bringing the air and air closer together, resulting in fine air into the air and an upward channel through the air. In contrast to other products it was developed not only for the purpose of oxygen input, but also for the task of mixing and is tailor made especially for carrying out this double task.

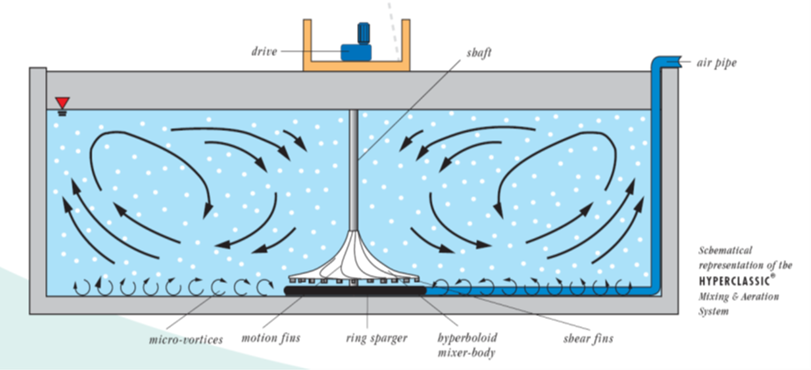

The hyperboloid mixer/aerator rotates close to the bottom and its integrated and specially optimized motion fins thus produce a bottom flow which is directed radially outwards. Particularly at the bottom, this flow is highly turbulent and thus effectively whirls up any depositions. Along the walls the flow rises upwards and transports all particles until they are just below the water surface. Due to the overall flow which forms in the activated sludge tank an intensive mixing of the activated sludge is achieved.

There are multiple areas of application for the HYPERCLASSIC ® Mixing and Aeration System. Basically, it can be used for all aeration tasks, especially in all variations of the activated sludge process, such as:

- For BOD/COD reduction and nitrification in conventional activated sludge plants

- in membrane bio reactor plants (MBR)

- in Sequencing Batch Reactor plants (SBR)

- in swing zones with facultative denitrification/nitrification

- in pure oxygen plants

- for BOD/COD reduction as well as nitrificationin carousel tanks, oxidation ditches or aeratedponds.

- Optimal bubble sizes are produced and particularly high detention times are achieved, because of the air introduction at the tank bottom with radial distribution.

- Highest oxygen transfer and yield levels are therefore achieved.

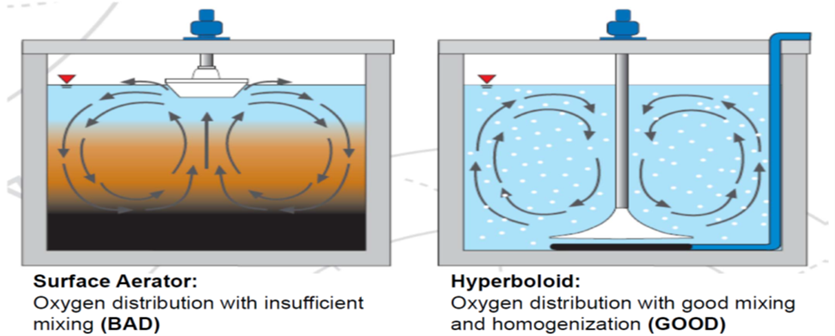

- The oxygen concentration is distributed homogeneously throughout the tank.

- The activated sludge flocs are optimally supplied with oxygen to their core. This improves the sludge quality immensely - especially the sedimentation qualities in the secondary sedimentation tanks.

- The activated sludge flocs are distributed throughout the tank, sedimentation is avoided with certainty.

- Production of aerosol and its associated hygienic and aesthetic problems no longer exist. Protective covers are superfluous.

- There is no noise emission worth mentioning. Sound covers are normally superfluous.

- The energy, installation and maintenance costs and thus the operating costs are reduced to a minimum.

- The system is absolutely non-clogging, there is no wear of membranes and no increase in loss of pressure.