Wastewater Treatment With Sludge Drying Bed Techniques

The principle in handling this sludge is a method / system that functions to store liquid sludge. This system is divided into two systems, namely;

- Low air content mud,

- Filtrate / water, which must be returned to the process (initial / middle)

In this article, the writer divides it into two ways, namely;

1. Mechanical Way

As we already know, many manufacturers of wastewater treatment equipment in the world make equipment (machines) with sewage sludge treatment. Some of them are as follows;

- PRESS FILTER BELT

In the use of this machine, the mud is clamped / squeezed in the middle of 2 porous belts by using high pressure roll clips, - CHAMBER FILTER PRESS

This machine is used by inserting the sludge into square bags with a porous frame lined with high pressure until the water is squeezed out and the solid mud is trapped in. - CENTRIFUGE

In principle, this method is the same, where the mud is inserted into a round tube in which there is a screw where the end of the tube is tapered / conical at the end. Likewise with the thread / screw distance / pitch which is getting tighter at the end side. Thus, the sludge will experience high pressure squeezing, which results in a separation between the mud and water.

2. Manual way

- SLUDGE DRYING BED (SDB)

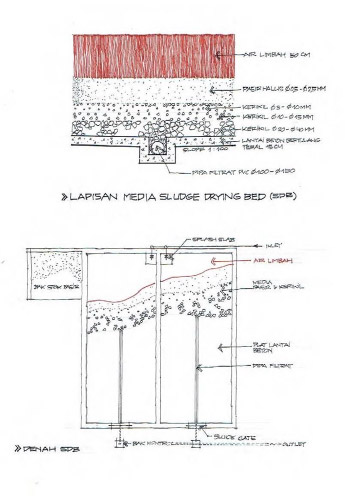

In this method, the process is to manually dry the sludge obtained through sunlight (Evaporation / Evaporation). Liquid sludge from the deposition building (both first and second), is put into a tub that has a composition of sand and gravel media with different sizes and thickness variations, where the bottom layer is coarser and the upper part is the smoothest (fine sand).

At the bottom of the tub, a perforated filtrate pipe is planted which will drain the relatively free filtrate / water from the sludge out to the collecting tub. A layer of mud will be left on the sand and dry (cracked) by itself by the hot sun, which is commonly known as a "sludge cake".

In this process, the pouring height of the liquid slurry should be examined by observation, so that the final thickness of the sludge cake is about 5cm above the fine sand layer. Sludge is generally black or brown in color, with a rough and cracked surface.

COMPARISON OF MECHANICAL AND MANUAL MUD HANDLING

We can see a comparison of the types of requirements between mechanical and manual sludge handling below ;

| No. | Types of Mechanical | Requirements (BFP, CFP, CFG) | Manual (SDB) |

| 1 | Investments in machinery, etc. | Available & Expensive | None |

| 2 | Electricity and Water | Requires electricity & water | None |

| 3 | Chemicals | Requires chemicals | None |

| 4 | Labor | Max.2 people | Max.6 people |

| 5 | Land requirements | Small | Wider |

| 6 | Weather Disturbance | Disturbance | Very Disturbance |

| 7 | Time of Operation | Day & Night | Effective during the day when it is hot |

| 8 | Odor | Relatively odorless | Smelly, especially in the rainy season |

| 9 | Drying Area | Required | Not necessary |

| 10 | Temporary Shelters | Required | Required |

To deal with weather disturbances, especially when it rains, it is advisable to equip the Sludge Drying Bed with a transparent roof.

SLUDGE DRYING BED BUILDING CONSTRUCTION

The following is a description of the types of materials along with tips commonly used for the construction of Sludge Drying Bed buildings:

- The walls of the tub can be made of bricks as thick as one stone, or using river stones, with waterproof cement mortar, or it can also be made of reinforced concrete,

- The floor should be made of concrete, with a minimum thickness of 15cm and a concrete quality of K.175 using shrinkage reinforcement, and a slope of 1: 100 towards the drain pipe / filtrate.

- The sludge pouring inlet pipe valve should use a Ball Valve, with a liquid slurry pouring height of about 50cm above the sand surface.

- Installing the Splash Slab with the aim that the sand layer is not disturbed / eroded when filling the Sludge Drying Bed tub,

- Filtrate / drain pipe PVC dia, 100 - 150mm, perforated dia, 16mm spacing 250mm at 4 o'clock and 8 o'clock direction to collect and flow the filtrate. PVC pipe connections may be made without gluing.

- Fine sand stock bath as a reserve for the addition of reduced sand when taking sludge cake,

- The control tub is located at the end of the filtrate pipe outside the building for maintenance if the filtrate pipe is dirty,

- If possible, make SDB tanks above a high enough elevation, so that the filtrate water can flow to the nearest collection tank, where it can be simultaneously pumped back into the process building for later processing.

DRYING DETAILS SLUDGE DRYING BED

IMPLEMENTATION OF WWTP ( Waste Water Treatment Plant ) SLUDGE DRAYING BED IN PJ / PJL PROJECTS

- WWTP Rungkut Industri in Surabaya, carried out by Passavant Werke Gmbh with PT, Panca Jasa in 1981,

- WWTP Jababeka Industrial Estate in Cikarang in 1991, which is currently equipped with a Belt Filter Press, with an area of ��17 Sludge Drying Beds @ 10 x 30mtr, a total of 5100 m2,

- WWTP Pasuruan Industrial Estate Rembang - development of PT Industrial Estate, SIER in Kab, Pasuruan,

- WWTP PT Tarunakusuma Purinusa - Bawen - Kab, Semarang which is currently also equipped with a centrifuge.